Description

Beckhoff CNC system

Machine equipped with Bechhoff CNC system, with Ether CAT real-time control protocol,reduce machine down time and ensure fast response. Besides, the extended automation system and application s can be easily integrated into machine thanks to the open automation systems of Beckhoff CNC.

Fully enclosed housing

Full yen closed housing,Safety circuit design, equipped with laser radiation-shielding glass, Hig her safety standard, Ensure the safety of operators.

Direct drive system with High torque servo motor

Synchronous drive system on both sides of cutting bridge,Equipped with high torque direct drive system. Ensure the powerful driving, high accuracy cutting and excellent dynamic response.

Servo-control valve of cutting gas pressure

Programmable Cutting gas thanks to Servo-control valve, it can switch the type of cutting gas automatically, and accurate control the gas pressure without user intervention,use friendly and reduce gas consumption .

Features

Better laser beam quality, lower operating costs,less power consumption and longer working life due to using the new generation IPG fiber laser source ;

Equipped with PRECITEC new generation pro-cutter laser cutting head, Optimized cutting process, monitoring cutting conditions through“APP”use easily and friendly ;

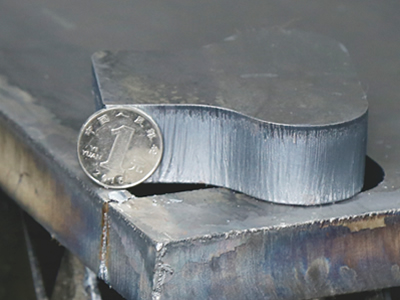

Eagle eye (CCD) technology, ultra-fast positioning the sheet metal edge, minimum cutting down time, In addition, it also can process punching parts and precut parts, due to secondary positioning function;

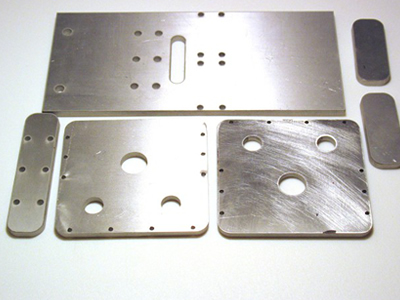

Optimized cutting technology with Programmable laser frequency and focus position, to achieve high efficiency processing on different thickness & type sheet metal. All cutting parameters can be programmed, no need human intervention, use easily and friendly;

Automatic energy saving mode: while stop over 5 minutes, machine automatically switch into “standby” mode, to reduce power consumption;

Auto exchanging table with Hydraulic lifting system; ensure synchronous running, reliable and stable;

With remote function, can remotely monitor the running conditions of machine, much easier for service and faster response;

With ergonomic design, equipped with intelligent operation terminal, user-friendly and easy to learn.

Specification

| Model | M3015 Fiber Laser Cutting Machine |

| Output laser power | 1-20KW |

| Working area | 3050*1550mm |

| Material size | 3000*1500mm |

| Position accuracy | ±0.05mm / m |

| Reposition accuracy | ±0.03mm/ m |

| X/Y axis maximum single axis positioning speed | 170m/min |

| X/Y axis maximum linkage speed | 240m/min |

| Maximum positioning acceleration | 2.4g |

| X axis stroke | 3050mm |

| Y axis stroke | 1550mm |

| Z axis stroke | 100mm |

| Maximum machining weight of a single table | 1500kg |

| Gross weight | 7500kg |

| Exchange table weight | 2500kg |

| Overall dimension | 9000*3100*2200mm |

Application